Eliminate Heat Pump Odors in Alvin: Causes & Remedies

Replacing an oil heating system is a significant long-term investment and a big decision that affects comfort, monthly bills, and your home’s environmental impact for years to come. This comprehensive guide breaks the process down into clear, practical steps so you can compare alternatives, understand likely costs, and spot the important trade‑offs. Whether you’re dealing with an aging furnace that’s seen better days or struggling with high operating costs that strain your budget, knowing your options helps you choose a solution that performs better and costs less to run. Below we’ll cover why owners replace oil systems, the best alternatives available today, typical costs involved, and the benefits of working with a trusted local HVAC team like Davis Mechanical Contractors.

Why Replace an Oil Heating System?

Upgrading an old oil furnace can dramatically improve efficiency, significantly lower fuel use and bills, and make your home more comfortable—often with a smaller carbon footprint. Older oil equipment, especially units 15-20 years old or more, usually runs at efficiencies as low as 60-70% AFUE (Annual Fuel Utilization Efficiency), leading to substantially higher operating costs compared to modern systems. More homeowners and businesses are also choosing cleaner options for environmental reasons, aiming to reduce their contribution to greenhouse gas emissions. Spotting the signs your oil system is wearing out makes it easier to act proactively before repairs become frequent, expensive, and ultimately unsustainable.

What Are the Signs Your Oil Furnace Needs Replacement?

Look for a few clear warning signs that indicate your oil furnace is nearing the end of its operational life or is becoming a financial burden. These include equipment older than about 20 years, which is typically beyond its expected lifespan, and rising repair bills that might exceed 30-50% of the cost of a new system annually. A noticeable drop in heating performance, such as frequent cold spots in your home or the system struggling to reach desired temperatures, is another strong indicator. If your energy bills climb unexpectedly by 10-20% or more without a corresponding increase in usage, or if your home no longer heats evenly, those are strong clues your furnace is losing efficiency and may be due for replacement.

How Do Operating Costs and Environmental Impact Influence Replacement Decisions?

Fuel price swings and growing environmental concerns are major reasons homeowners and businesses switch away from oil. Heating oil prices can be highly volatile, fluctuating by 20-50% or more annually, making budgeting unpredictable. Furthermore, burning heating oil produces more greenhouse gases, particularly carbon dioxide (CO2) and sulfur dioxide, than many modern alternatives. Moving to a more efficient or lower‑carbon system can reduce both your long‑term costs by hundreds or even thousands of dollars per year and significantly shrink your home’s environmental footprint—something increasingly important to many families and businesses striving for sustainability.

What Are the Best Alternatives to Oil Heating Systems?

Several excellent alternatives to oil heating are common today, each offering distinct advantages. Each has strengths and trade‑offs, so the right choice depends on your home’s specific characteristics, local fuel prices, and priorities like maximum efficiency, lowest emissions, or upfront cost. Below we summarize the most typical options to help you compare and make an informed decision.

How Do Heat Pumps Compare as an Oil Heating Alternative?

Heat pumps are a popular, highly energy‑efficient option because they move heat rather than generate it, making them up to 300-400% efficient (a Coefficient of Performance, or COP, of 3-4). They provide both heating and cooling from a single system and can cut energy use significantly, often reducing heating bills by 30-70% compared to oil. Their performance depends on the model and the climate—modern cold‑climate heat pumps are designed to operate effectively down to -15°F to -20°F, doing a much better job in cooler areas than older designs. They are an excellent, environmentally friendly choice for many homes, especially when paired with a well-insulated structure.

What Are the Pros and Cons of Natural Gas and Electric Furnaces?

Natural gas furnaces are generally highly efficient, with modern units boasting AFUE ratings of 90-98%, and are cost‑effective where a gas line exists. They offer strong, consistent heat at a significantly lower operating cost than oil in many markets, often saving homeowners hundreds of dollars annually. Electric furnaces are simple to install, require minimal maintenance, and reliably warm a home, achieving 100% efficiency in converting electricity to heat. However, they can be more expensive to run depending on local electricity rates, especially in regions with high utility costs. Weigh installation access, current and projected fuel price trends, and your comfort needs when choosing between them.

When Is a Hybrid Heating System the Right Choice?

Hybrid heating systems, also known as dual-fuel systems, combine a high-efficiency heat pump with a traditional furnace (typically natural gas or propane) and intelligently switch between sources to maximize efficiency as outdoor temperatures change. They’re a great fit if you want the exceptional efficiency of a heat pump for most of the year but need the powerful, reliable backup of a furnace on the coldest days—for example, when temperatures drop below 30-40°F. This setup can offer the best of both worlds, providing significant energy savings while ensuring comfort even during severe winter weather, making them ideal for regions with variable winters.

What Key Factors Should You Consider Before Replacing Your Oil Heating System?

Before you choose a replacement, it’s crucial to weigh several practical factors so your new system is perfectly suited to your home and long-term goals. These considerations ensure optimal performance, efficiency, and comfort.

How Do Energy Efficiency Ratings Impact Your Heating System Choice?

Energy efficiency ratings are critical metrics that directly impact your operating costs and environmental footprint. Look at efficiency metrics like AFUE (Annual Fuel Utilization Efficiency) for furnaces, which indicates the percentage of fuel converted into usable heat (e.g., 95% AFUE means only 5% of fuel energy is lost). For heat pumps, consider SEER (Seasonal Energy Efficiency Ratio) for cooling and HSPF (Heating Seasonal Performance Factor) for heating. Higher ratings mean the system uses less fuel or electricity to deliver the same comfort, which translates to lower monthly bills and a smaller environmental footprint. Prioritize higher efficiency where it makes sense for your budget and home, as the initial investment often pays for itself through energy savings over 5-10 years.

Why Is Home Size, Insulation, and Local Climate Important?

Your home’s size, insulation quality, and the climate where you live are fundamental in determining the required system capacity and type. A well‑insulated home with modern windows and proper air sealing holds heat longer and can often use a smaller, more efficient unit, potentially saving on equipment costs. Climate significantly affects how well options like heat pumps perform; for example, a cold-climate heat pump is essential in regions with sustained freezing temperatures. A professional HVAC contractor will perform a detailed load calculation (often a Manual J calculation) to accurately size your system, preventing issues like short-cycling (where the system turns on and off too frequently) or inadequate heating.

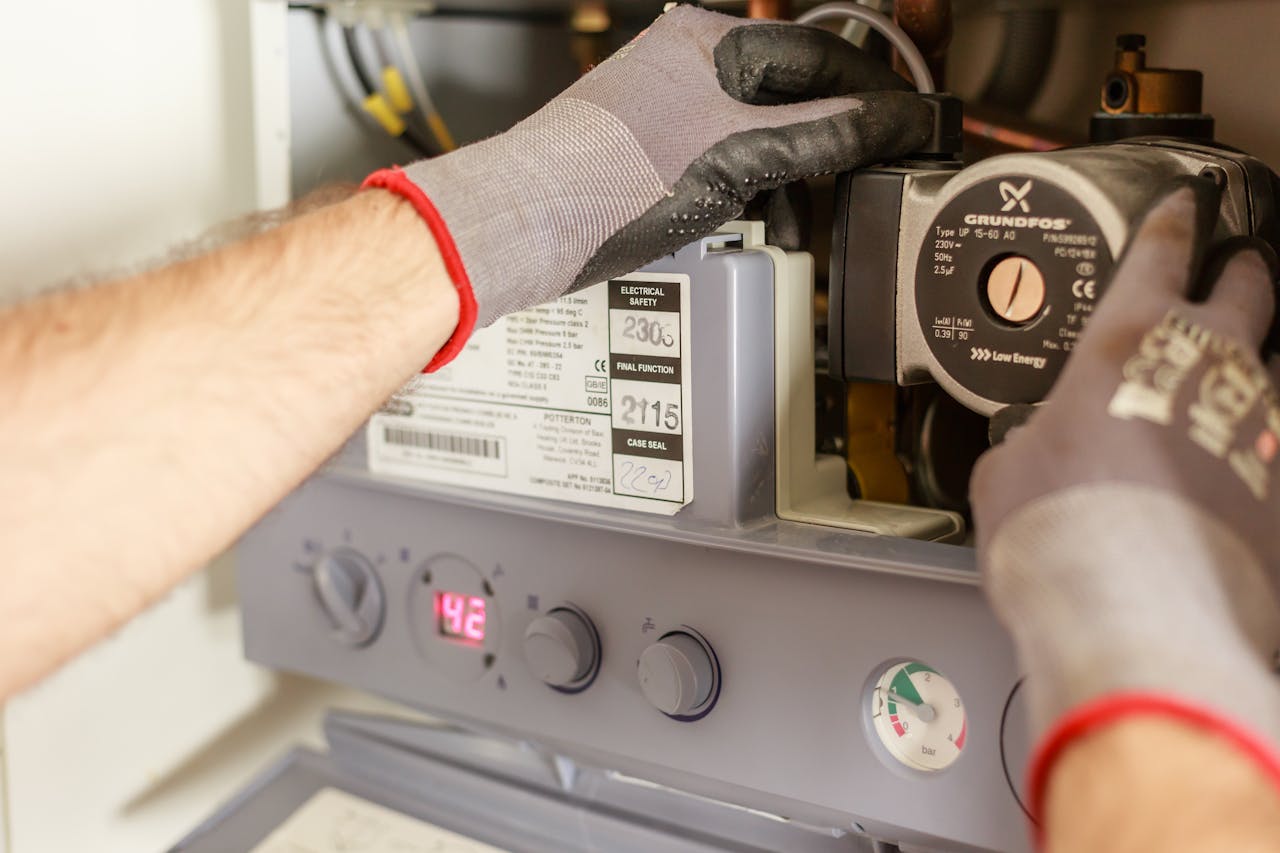

What Is Involved in Oil Tank Removal and New System Installation?

Replacing an oil system commonly requires removing the existing oil tank, which can be a complex process. This should always be done by qualified professionals to meet strict safety and environmental regulations, which often include pumping out residual oil, cleaning the tank, and proper disposal. The full installation of a new heating system may include tank decommissioning, significant ductwork modifications or additions, electrical panel upgrades, and gas line installation. Knowing these steps up front helps avoid surprises on schedule or cost, as permits for tank removal and new system installation can take 1-2 weeks to secure, and the entire process typically spans 1-3 days depending on complexity.

What Advantages Does Davis Mechanical Contractors Offer for Heating System Replacement?

Picking the right contractor makes a big difference in the success and longevity of your new heating system. Davis Mechanical Contractors brings extensive local experience, clear communication, and a proven track record of reliable installations to help you get the results you want, ensuring peace of mind and optimal performance.

How Does Local Expertise Benefit Your Heating System Upgrade?

We know Alvin, TX and the surrounding area intimately—what systems perform exceptionally well here given our specific climate, local code requirements, and common installation challenges unique to our region. That local knowledge helps us accurately size and install systems for dependable, efficient operation over the long term, accounting for factors like high humidity, specific soil conditions for geothermal options, and local utility infrastructure. Our technicians are familiar with all local permitting processes and ensure every installation meets or exceeds regional standards, guaranteeing compliance and safety.

What Financing and Warranty Options Are Available?

Davis Mechanical Contractors understands that a new heating system is a significant investment. That’s why we offer flexible financing plans to help spread your investment over manageable monthly payments, often with competitive interest rates or special promotional periods like 0% APR for 12-60 months for qualified customers. We also provide robust warranties that protect both the equipment (typically 10-year parts warranties) and our workmanship (often 1-2 year labor warranties). These options give you financial flexibility and invaluable peace of mind, knowing your investment is protected long after installation.

How Can You Get Started with Replacing Your Oil Heating System?

To get started on your journey to a more efficient and comfortable home, contact Davis Mechanical Contractors for a free, no-obligation estimate. Our experienced team will conduct a thorough evaluation of your home, explain suitable options in detail, and recommend a personalized plan that perfectly balances comfort, efficiency, and your budget. Scheduling is straightforward, and our certified technicians manage the entire project from the safe removal of your old system through final testing and tuning, ensuring your new system runs right from day one with optimal performance.

Different systems offer different advantages—compare performance, costs, and environmental impact to pick what’s best for your home.

| Heating System | Efficiency Rating | Typical Cost Range (Installed) | Environmental Impact |

|---|---|---|---|

| Heat Pumps | 200-400% (COP 2-4) | $6,000-$12,000 | Very Low (Zero direct emissions) |

| Natural Gas Furnaces | 90-98% AFUE | $4,000-$6,500 | Moderate (Lower CO2 than oil) |

| Electric Furnaces | 100% AFUE | $3,000-$5,500 | High (Depends on electricity source) |

Replacing an oil heating system takes careful planning, but with the right information and a trusted local contractor, you can make a smooth transition to a more efficient, comfortable, and environmentally friendly solution.

Frequently Asked Questions

What maintenance is required for new heating systems after installation?

Regular maintenance is crucial to keep your new system reliable and efficient for its full lifespan, typically 15-20 years. Schedule an annual inspection with a certified HVAC technician to clean components, check electrical connections, calibrate controls, and replace filters (which should be changed every 1-3 months by the homeowner). Also, keep the area around the outdoor unit clear of debris and follow any specific manufacturer maintenance tips. Routine care prevents small issues from becoming big repairs, helps preserve efficiency, and often maintains warranty validity.

How can I determine the right size heating system for my home?

Choosing the right size heating system requires a professional heating load calculation, often referred to as a Manual J calculation. This detailed assessment accounts for your home’s square footage, ceiling heights, insulation levels (R-values), window types and orientations, air infiltration rates, and local climate data. A professional HVAC contractor can perform this calculation to size your system accurately. Proper sizing prevents common issues like short‑cycling (an oversized system turning on and off too frequently, leading to uneven heating and wear) and ensures comfortable, efficient operation without wasting energy.

What are the environmental benefits of switching from oil to alternative heating systems?

Switching away from oil typically leads to a significant reduction in greenhouse gas emissions and overall energy use. Heat pumps are especially beneficial because they move heat rather than create it, making them 2-4 times more efficient than traditional heating systems and producing zero direct emissions. Natural gas usually emits about 25-30% less CO2 than heating oil. Over time, higher efficiency and cleaner fuel sources substantially reduce your home’s environmental footprint, contributing to better air quality and a more sustainable future.

Are there any specific local regulations regarding oil tank removal?

Yes, local rules for oil tank removal vary significantly by municipality and state, and many areas require licensed professionals to decommission and dispose of oil tanks. These regulations often include requirements for pumping out residual oil (typically 10-50 gallons), cleaning the tank, soil testing for contamination, and proper disposal of the tank itself. Failure to comply can result in substantial fines (potentially thousands of dollars) and environmental liabilities. Always check with local authorities or ask your contractor to handle all necessary permits and ensure safe, compliant removal.

What should I expect during the installation process of a new heating system?

The installation process typically starts with a home assessment and the safe removal of your old equipment and oil tank if needed. Technicians then install the new system, which may include significant ductwork modifications, electrical panel upgrades, or new gas line work. Most standard installations take one to two days, though more complex conversions (e.g., adding ductwork for a heat pump in a home previously heated by radiators) can take three to five days. Finally, the crew thoroughly tests and tunes the system to ensure optimal performance and efficiency before providing a walkthrough and handing it off to you.

How do I choose the best HVAC contractor for my heating system replacement?

To choose the best HVAC contractor, look for local companies with extensive experience installing the specific type of system you want, strong customer reviews (check platforms like Google, Yelp, and the BBB), proper licensing and insurance, and clear warranties on both equipment and labor. Get at least three detailed quotes, ask specific questions about the proposed equipment, installation process, and post-installation support. Choose a team that communicates clearly, provides transparent pricing, and stands behind their work with a solid reputation for quality and customer satisfaction.

Conclusion

Upgrading from an oil heating system can deliver better comfort, significantly lower bills, and fewer emissions, making it a smart investment for your home or business. By carefully comparing your options, checking available incentives, and working with a trusted local contractor like Davis Mechanical Contractors, you’ll find the right system to meet your specific needs. Ready to take the next step towards a more efficient and comfortable future? Contact us for a free estimate and let our expert team guide you to a smarter, more efficient heating solution.